note : The ink in this copy is thin and light; these scans have been processed in a more pronounced way than others in order to bring out the writing; some are gray scale. I have listed all topics as found, but transcribed only about half of these. Those omitted are generally longer and/or involve computations or tabular presentation of data; some of these pages are presented in the scans. My transcriptions generally respect Flagg’s casual orthography as it is found.

The contents of John Flagg’s copy of Index Rerum is technical, save for two pages of draft petitions

under PeeP. Its entries run ca 1860-1864. Written in ink on the front flyleaf is :

John H. Flagg,

Mittineague, Mass.

June 18th 1860.

Internal evidence suggests that Flagg was a master machinist at the Portsmouth Navy Yard, was a resident of Dover, New Hampshire, and was familiar with power trains and foundation work at various New England mills, from New Jersey north. I have not found external information about Flagg, to date.

Flagg’s copy is not a record of reading, but rather what might best be described as a personal ready reckoner.

- Area. To find the Area of a circle. Square the diameter and multiply by .7854.

- Angle. How to get one. First strike a straight line. and then from a point, say A. describe a circle of 60d (from the scale of chords) Then from the scale if you want 45 d place the dividers on that numer and frm the point where the circle intersects the straight line, draw an arc intersecting the circle and from this intersection draw a line to the point A. and you have the angle.

- Angles. To get the angle for Tooth of Gear to run in worm. Lay a plane the length of the circumference of the worm. then raise the perpendicular the distance between the threads on worm. No 10 is 1/10 of inch &c. Then draw a line from end of line to end of perpendicular. This gives the angle.

- Atmosphere. Is calculated to be 45 miles high & weighs 15 lbs to square inch.

- Bearings Heavy. For glazing look at Glazing.

- Beams for Looms. It is customary to alow [sic] a beam and one half to a loom.

- Bricks. Twenty four Bricks when laid in Cement or Mortar are considered a solid foot by the H. F. Co.

- Bridge (Truss). A Bridge 18 ft wide. Stringers 9 by 10 of pine. Truss 9 × 10 chestut. Cross Ties 5 × 10 2 ft 2 in apart. 3 in Plank, Chestnut, can be built for 4.00 per ft, including every thing.

- Bobbins. Cost of coarse speeder 6 1/2 in head and 10 in traverse $70.00

Cost of speeder 5 in head and 7 in traverse $55.00

Warp Spinning 2 1/2 in $7.00

Filling Spinning 2 1/2 in $7.00 - Bushel

- Bushel (Coal)

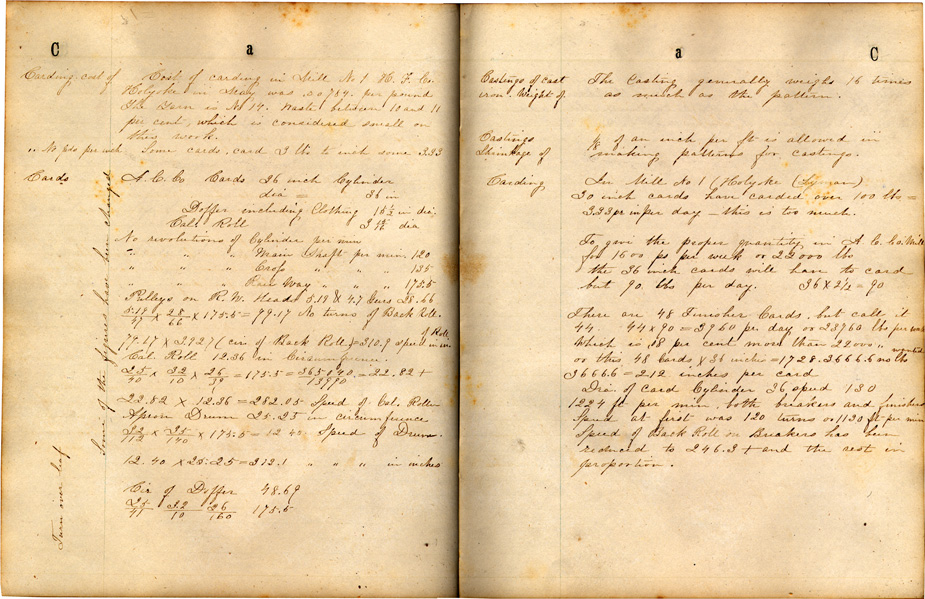

CaaC

- Carding, cost of.

- Cards.

- Castings of cast iron, weight of.

- Castings, shrinkage of.

- Carding.

- Cement for belting.

- Circle. To find the circumference multiply the diameter by 3.14159.

- Radius

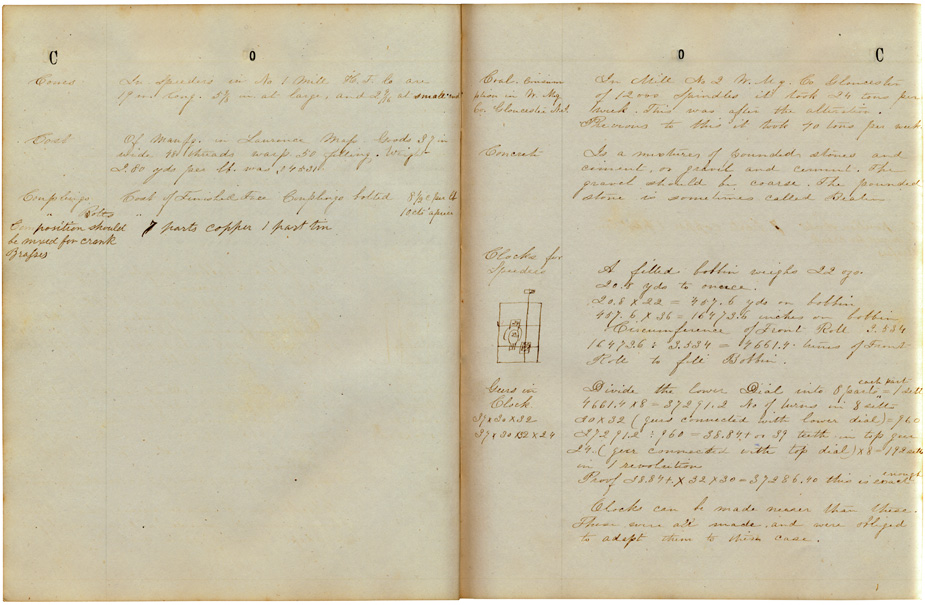

CooC

- Cones

- Cost, or manfg. in Laurence Mass. Goods 37 in wide 48 threads warp. 50 filling. Weight 2.80 yds per lb. was .04531.

- Couplings, cost of.

- Coupling bolts. Composition should be mixed for crank brasses, 7 parts copper 1 part tin.

- Coal Consumption in W. Mg. Co. Gloucester

- Concrete

- Clocks for Speeders

- Gears in Clock

- Dam

- Drawing Frame

- Rail Way Head

- Drawing Frame

- Drawing Frames as changed. See next page.

- Draughts

- Drawing Frame

- Dressing, cost of.

- Draught on Drawing.

- Dressing, Cost of in Chicopee

- Diameter. To find the dia. of a circle, divide the circumference by 3.14159.

- Drills. Long face cams throw the twill on under side of cloth on Loom. Short face on top side. Throw the [ ] as low as can be done to make the twill show to best advantage.

- Drums

- Engine Lathe

- Fans. All Fans of Blowers should be perfectly balanced or they will cause a great jarring and will wear out much quicker.

- Flyers

- Foundations for Cotton Mills and other Large Buildings. The foundations for such buildings ought to be laid below the frost and on gravel if possible. Foundations for H. F. Com. Mills are laid 14 ft deep. 6 or 8 ft are wide enough for good bottom. No 7 mill at Cabot is laid on 3 in plank. The plank botton is about 3 ft wider than the stone work

- Forks Loom. Cost of at Mason's finished Mal’ble iron. 25 each

- Gas, March 1852. The cost of Gas used in Washington Manfg. Co. Gloucester, N.J. varied from 1.67 to 1.80 mills per foot. It was made of resin which cost delivered at the mills 80 cts per barrel. At the present price of resin 2.00 per Bbl Gas can be made cheaper of coal. Resin Gas is more brilliant than coal. To file Make Sheet of the Gas then pour Alcohol on water till it runs out of the side play, then draw off a small quantity out of the bottom put on gas, and go it [?].

- Glazing for Heavy Bearings

- Galvanizing Iron. The iron is first clensed [sic] thoroughly by immersion in dilute suphuric or muriatic acid. (1 part acid to 1 pt water) and subsequent hammering and scouring with sand and emery. The iron thus prepared is now plunged into melted zinc covered with salammoniac and the process is complete. If the iron be cleansed and dipped in solution of zinc in commercial muriatic acid a film of zinc will deposit.

Copper may be deposited on iron by cleaning the iron and dipping it in saturated solution of sulfate copper. Would recommend that the iron be first boiled in lye, washed in water then cleansed of rust by immersion in acid diluted as above, then scoured with sand, washed in pure water and finally plunged into the sulphate bath. The deposition of the copper may be much facilitated by use of a small galvanic battery. Attach the iron the the negative (zinc) pole and a plate of copper to the positive (copper) pole and plunge both in Sal Sulphate sol: Taking care to keep them apart.

If you wish to deposit silver or gold on iron you must first copper the iron as above then remove wash and transfer (still continuing connection with the batter to a salution [sic] of silver or gold in cyanide of potassium. Substituting a silver or gold coin for copper plate, any thickness may be obtained by adding a small quantity of Bisulphide carbon to the cyanide solution a polished surface is obtained.

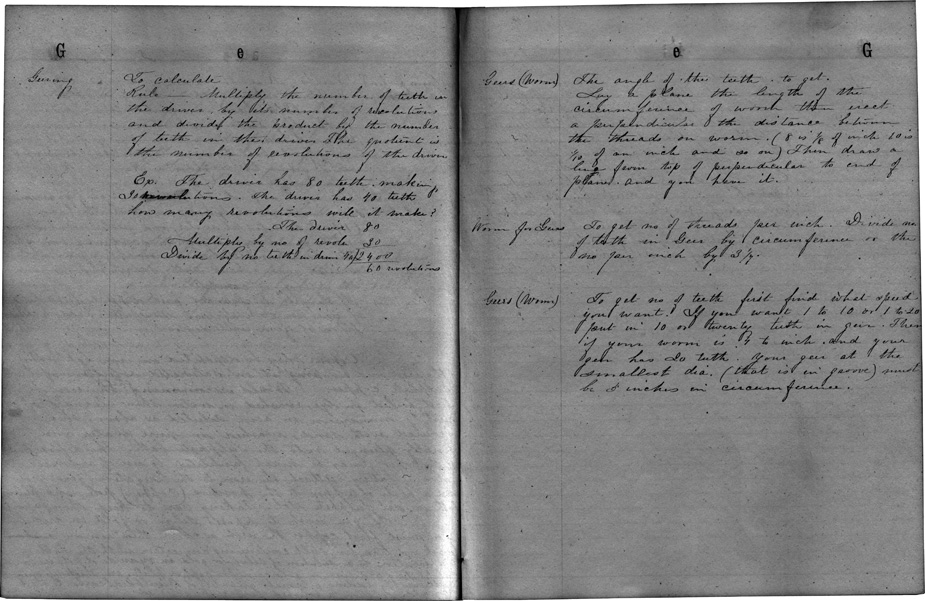

GeeG

- Gearing. To calculate

Rule — Multiply the number of teeth in the driver by its number of revolutions and divid the product by the number of teeth in the driver. The quotient is the number of revolutions of the driver.Ex. The driver has 80 teeth: making 30 revolutions. The driver has 40 teeth. How many revolutions will it make?

The driver 80

Multiply by no of revoln 30

Divide by no teeth in driver 40 ÷ 2400 = 60 revolutions - Gears (worm). The angle of the teeth . to get . Lay a plane the length of the circumference of work then erect a perpendicular the distance between the threads on worm (8 is 1/8 of inch 10 is 1/10 of an inch and so on) Then draw a line from top of perpendicular to end of plane . And you have it.

- Worm for Gears. To get no of threads per inch . Divide no. of teeth in Gear by circumference or the number per inch by 3 1/7.

- Gears (worm). To get number of teeth first find what speed you want. If you want 1 to 10 or 1 to 20 put in 10 or twenty teeth in gear. Then if your worm is 4 to inch . and your gear has 20 teeth . Your gear at the smallest dia. (that is in groove) must be 3 inches in circumference.

- Grout. To a mixture of sand and cement about equal parts, mixed with water so that it will run freely. It must be used immediately after making or it will set. and it must be made quickly or it will set while making.

- Harnesses for a loom. It is usual to allow one and one half set to a loom.

- Hanks. 7 skeins or 840 yrds make one Hank.

- Strength of Iron.

- Lathes. No 2 Gd [?] Head Hand Lathe 12 ft bed cost 165.00

No 2 Plain Head do do do do cost 145.00

No 3 Plain Head do do 6 ft do cost 67.00 - Looms, Speed of.

- Position take up for Looms

- Metre. Look at gas.

- Mill Cotton Power to drive. It is estimated that 18 horse power will drive 1000 spindles, with all the preparatory and finishing machinery, in a Mill that makes from No 20 to 30 yarn. using ring spinning.

Perhaps 18 horse is rather high. 18 horse power is sufficient to drive 1000 spindles of No 14 yarn ring spinning.

Further experiments show that 18 horse is not enough to drive 1000 spindles, ad the preparatory an dfinishing machinery, on No 14 yarn.

- Mule Spinning. On No 30 to 40

3 stretches per min. is about right for warp

3 for Filling. - Oval. To find the circumference of. Rule. Multiply the longest by the shortest dia. and that product by .7854 which will give the answer.

- Oil Consumption of in British Mills March 1852 [two pages]

- Plainer, Cost of. Paid Hadley Falls Co. for Plainer 4 1/2 ft bed (screw) 375.00

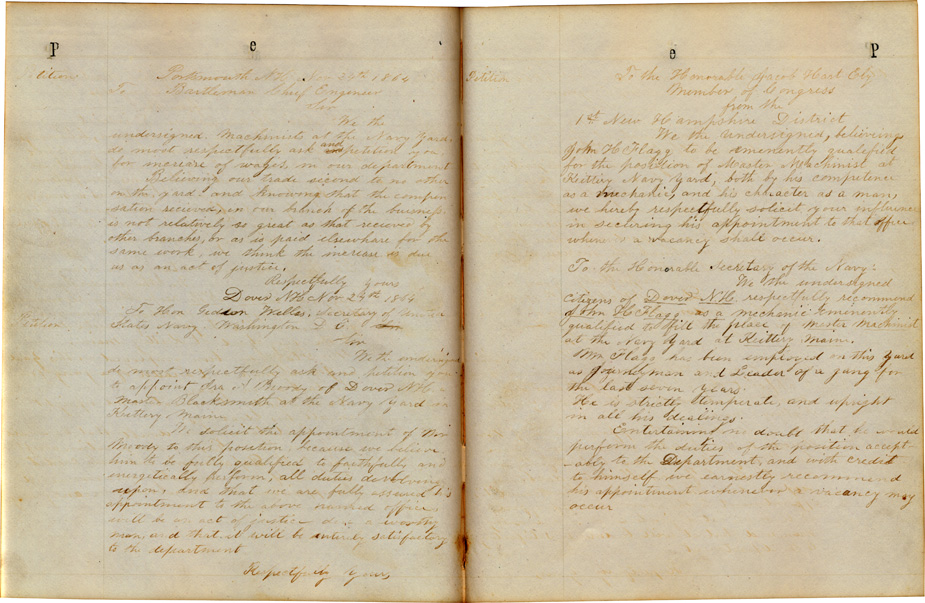

PeeP

- Petition

Portsmouth NH Nov 24th 1864

Bartleman Chief Engineer

Sir

We the undersigned, Machinists at the Navy Yard, do most respectfully ask and petition you for increase of wages, in our department.

Believing our trade second to no other on the yard, and knowing that the compensation received, in our branch of the business, is not relatively so great as that received by other branches, or as is paid elsewhere for the same work, we think the increase is due us as an act of justice,

Respectfuly yours - Petition

Dover NH Nov 24th 1864

To Hon Gideon Welles, Secretary of United States Navy, Washington DC

Sir

We the undersigned to most respectfully ans and petition you to appoint Ira A Moody of Dover NH, a Master Blacksmith at the Navary Yard, in Kittery Maine.

We solicit the appointment of Mr Moody to this position because we believe him to be fully qualified to faithfully and energetically perform all duties devolving upon, and that we are fully assured his appointment to the above named office, will be an act of justice [?] a worthy man, and that it will be entirely satisfactory to the department.

Respectully yours, - Petition

To the Honorable Jacob Hart Ely

Member of Congress from the 1st New Hampshire DistrictWe the undersigned, believing John H. Flagg to be eminently qualified for the position of Master Machinist at Kittery Navy Yard, both by his competence as a mechanic, and his character as a man, we hereby respectfully solicit your influence in securing his appointment to that office whenever a vacancy shall occur. - Petition

To the Honorable Secretary of Navy

We the undersigned, Citizens of Dover N.H. respectfully recommend John H Flagg as a mechanic eminently qualfied to fill the place of Master Machinest at the Navy Yard at Kittery, Maine.

Mr Flagg has been employed on this Yard as journeyman and Leader of a gang for the last seven years.

He is strictly temperate, and upright in all his dealings.

Entertaining no doubt that he would perform the duties of the position acceptably to the Department, and with credit to himself, we earnestly recommend his appointment whenever a vacancy may occur. - Petition

SaaS

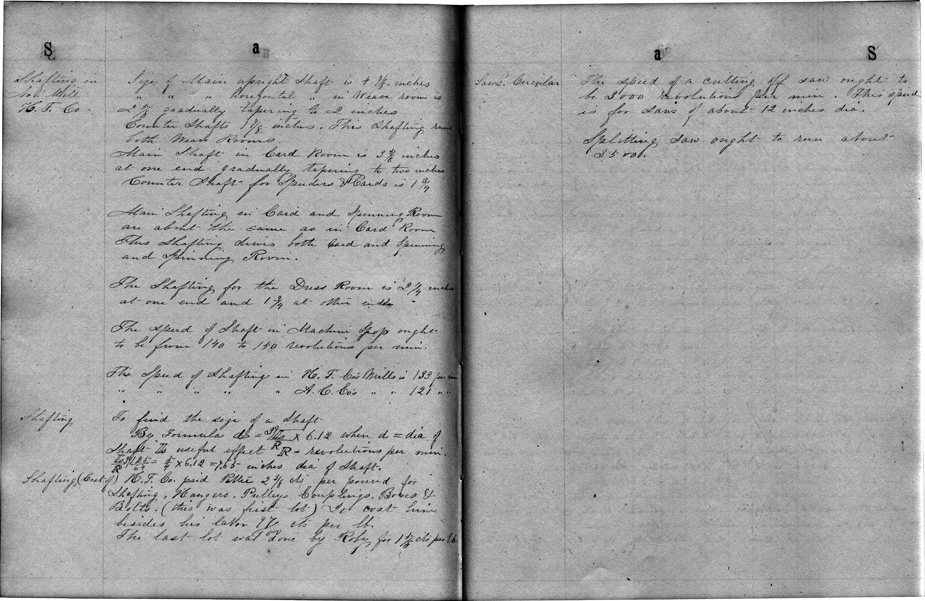

- Shafting in No. 1 Mill H.F. Co.

- Shafting

- Shafting (Cost of)

- Saws, Circular. The speed of a cutting off saw ought to be 3000 revolutions per min. This speed is for saws of about 12 inches dia.

Splitting saw ought to run about 3.5 vo. [?]

SeeS

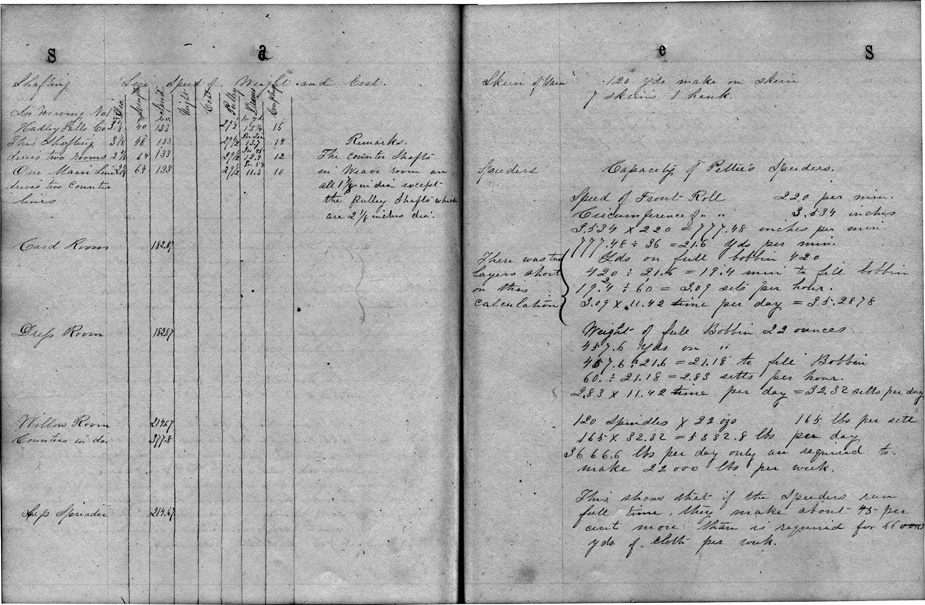

- Shafting

- Skein of Yarn

- Speeders

- Spinning, Cost of. The cost of Spinning in Mill No. 1 Hadley Falls Co. No 14 Yarn for the month of May was .0075 per pound. this is the average of Warp and Filling. The spindles averaged 7 34/100 [?] per day in last week in May.

- Stone Work. The stone for foundation of addition to Agawam Canal Co’s Mill cost delivered on Grounds

1.25 per perch

2.00 per perch for laying

3.25 whole cost per perch25 ft is one perch

These stones were brought about 2 1/2 miles

perch : a unit of cubic measure used in stonework, usually 16.5 feet (one rod) by one foot by 1.5 feet, or 24.75 cubic feet

- Supplys for Cotton Mills

- Shuttles. Price of Bandwins (Nashua) .35 cts each

TiiT

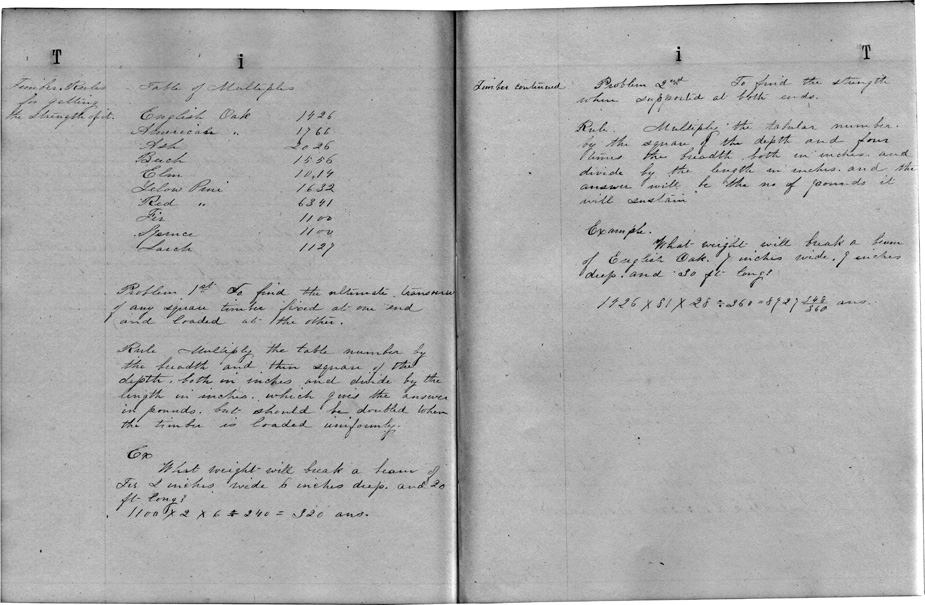

- Timber. Rules for getting the Strength of it.

- Turbin Wheel. Calculation for a wheel to drive 9216 spindles. [two pages of calculations]

Mr. Chase after this calculation, upon weighing by Dynonameter came to conclusion that it took 33 horse power to drive 1000 spindles with preparatory and finishing machinery.

Calculate 70 of c instead of 75 of c on power of wheel.

- Valve Safety

- Water. A column of water can be raised 33 1/3 ft high by a common lifting pump.

- Water. The theoretical velocity of the fall of. Rule. Extract the square root of the no of inches and multiply by 138.88

- Water in the Manfg of Cotton. The wash in H.F. Co. No. 1 Mill on No 14 cloth is between 10 and 11 per cent. This is considered low. Most mills would have made it 13 or 14 per cent.

- Weaving, Cost of. The average cost of weaving No 14 cloth of various widths from 3/4 to 6/4 in in No 1 Mill at Holyoke in May was .0048 per yd or .0138 per pound.

- Weaving, No. of Yds per Loom per day.

The Hadley Falls Co's Mill No 1 Holyoke averages

Of 3/4 Cloth No 14 75 yds per day

Of 4/4 cloth thin No 14 68 yds per day

Of 4/4 Cloth thick No 14 60 yds per day

Of 5/4 Cloth thick No 14 50 yds per day

Of 6/4 Cloth thick No 14 48 yds per day - Worms for Gears. See Gears.

- Yarn. Is guaged [sic] by the number of hanks there is in a pound.

Ex.

no 14 yarn there are 14 hanks per lb.

no 40 yarn there are 40 hanks per lb. and so on.120 Yds make a skein of yarn. 7 skeins or 840 yards make a hank.

The H.F. Company get about 1000 yards on filling and about 600 yds on warp bobbins No. 14.

44.855 yds dressed yarn No. 13 40 Picks make 40 yds cloth.